PIC FAQ Section

Frequently asked questions for

Microchip PIC 8 bit microcontroller programming

Table of Contents [Toc]

How I started microcontroller

programming

Why I use PIC microcontrollers

How to start with PIC

microcontrollers?

PIC16F84

PIC16F77

PIC16F877

Which development environment do I

use?

First steps in PIC programming

Valuable Quick

References

Common

programming questions

How to assemble PIC code in

MPLAB

Advanced steps in PIC

programming

General

Paging - large

code considerations

Using the MPLAB IDE

simulation infrastructure (MPSIM)

High-level languages

C

compiler

List of free C

compilers

Commercial C

compilers

Debugging hints

General

Compile messages &

sanity checks

Prevent

page crossings of tables

RS232 communication

issues

LCD communication

issues

In case of errors

Compile

errors

Page crossings

PIC history

Call it RISC...

Scientific

curiosity

From I/O handling to

RISC controller

How I started

microcontroller programming [Toc] [Top]

I first entered the microcontroller world with a proprietary,

mask-programmed controller kit bought from Conrad Electronics, a

german electronics distributor. It was a Conrad C-Control

Basic kit, a 68HC05B based controller board with RS232 link

and an external serial EEPROM as program memory. The user

develops its application in a kind of BASIC programming language,

which is afterwards translated by the development software into

byte-tokens. The byte tokens are then loaded into the serial

EEPROM. During execution, the controller reads these byte-tokens

from the external EEPROM and interprets them using the internal,

pre-programmed routines. For first contact with microcontrollers,

it was a good approach, although there were some unsatisfying

facts:

- proprietary solution using mask-programmed routines in the

controller

- rather slow execution and low performance

- very limited data RAM

- no tight control of hardware resources and its

capabilities

- an expensive solution if used in pervasive computing (a

single and simple mask-programmed controller unit without board

costs about 25 US-$)

These reasons have led me to change to another controller

solution. Finally, I decided to change to the Microchip PIC

controllers.

Why I use PIC

microcontrollers [Toc] [Top]

The Microchip PIC microcontrollers are a convenient and

cost-effective solution for a lot of home-made applications,

because:

- PIC microcontrollers are widely available (Farnell, Conrad,

Disterelec,...)

- PIC controllers are cheap and do not require a lot of

prerequisites before running in an application (i.e. additional

HW blocks such as external EPROM for program memory, external

A/D converter,...)

- the PIC development environment is freely available and

up-to-date

- there is a broad range of different PIC microcontrollers,

very likely to fit into your target application

- the hardware programming itself is easy and does not

require a lot of additional equipment (like JTAG programmer,

EPROM/flash programmer)

- the various packages available (DIP, SSOP, SOIC, TQFP,

PLCC,...), even with low pin counts, allow for convenient

prototyping without big initial efforts

Although I use PIC microcontrollers often, I would not

consider the PIC microcontroller as high-performance RISC

controller - as claimed by the manufacturer. High-performance -

compared to what? There is no reference for comparison

given...

On the other hand, I personally would implement a more

sophisticated architecture based on one instruction per

oscillator cycle, i.e. 1 MIPS @ 1 MHz. This is more

power-efficient and would at least indicate that there is best

use made of every clock cycle when using a single execution

pipeline. For the core, I would check the requirements carefully

and decide whether to use a two, three or four stage pipeline.

And for not loosing any performance, additional delayed-branching

would be introduced. A deeper stack for the program counter may

also be suitable, especially when serving a lot of interrupt

sources and doing prioritized interrupt handling in software

(i.e. another high-priority ISR call during a low-priority ISR

call). Finally, an ability to check the stack levels used would

also be welcome, as well as hardware-based context save on

entrance and exit of the interrupt service routine.

How to start

with PIC microcontrollers? [Toc] [Top]

I started with the PIC16C84 (an early EEPROM version of

today's standard flash version 16F84).

Today, I would say, the PIC16F84 is the best-suited Microchip

RISC controller to start with:

PIC16F84

- reasonable hardware complexity for beginners

- only 35 RISC instructions

- easy to program, even with self-made PIC programmers

(search the web)

- sufficient performance for ordinary

controller-applications, up to 5 MIPS @ 20 MHz

- 8-level deep hardware stack (for calling sub-routines)

- has internal and external interrupt support (e.g. timers,

port change), total of 4 interrupt sources

- ability to store non-volatile data in internal EEPROM (64

bytes)

- 18 pin package (DIP18)

Once you have acquired some experience in PIC programming and

you are familiar with the PIC architecture, I suggest to switch

to the PIC16F77 (that's what I did also). It offers a lot of

peripheral hardware blocks, so that you don't have to handle this

in software (e.g. RS232 transmission and reception):

PIC16F77

- instruction set is the same as for the PIC16F84

- much larger instruction memory (8k words) and data RAM (368

bytes), but no internal EEPROM (non-volatile data storage)

- provides many additional hardware resources, e.g.

- universal synchronous asynchronous receiver transmitter

(USART) for RS232 or similar interfaces

- synchronous serial port (SPI) with SPI master mode and

I²C slave mode

- parallel slave port

- capture/compare/PWM blocks

- 8 bit A/D converter (8 channels)

- total of 12 interrupt sources (internal and external

interrupts)

- 40 pin package (DIP40)

You can also switch directly to the PIC16F877, which offers

additional peripheral interfaces, especially if you want to

connect some I²C peripheral components:

PIC16F877

- same pin-out as the PIC16F77

- superior features compared to PIC16F77:

- 10-bit A/D converter (8 channels)

- I²C master mode

- internal EEPROM (256 bytes non-volatile memory)

- analog comparators

- total of 15 interrupt sources (internal and external

interrupts)

- self-reprogrammable under software control

(boot-loader)

- 40 pin package (DIP40)

Get the latest data sheets at www.microchip.com

Which development

environment do I use? [Toc] [Top]

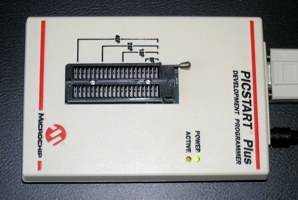

I started with the PICSTART Plus development programmer from

Microchip in 1998, and I still use the same programmer today:

- PICSTART Plus Programmer: with firmware v4.30.04

(software-upgradable), RS232,

costs about 200.00 US-$, ordering information

- In-Circuit Debugger 2: (ICD2) bought recently,

USB1.1 & RS232,

costs about 200.00 US-$ with 40 pin ICD header and

power supply, ordering information

- Microchip MPLAB IDE v8.50: free development

environment using PIC assembler

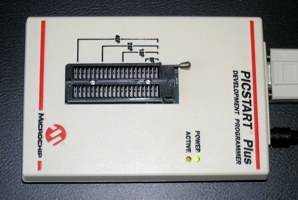

PICSTART Plus Programmer

from Microchip, incorporates the flash-upgrade kit and

latest firmware

(#DV003001,

~200.00 US-$)

|

|

In-Circuit Debugger 2 (ICD2)

from Microchip, allowing to debug the current processor

state, internal registers and EEPROM data by setting

breakpoints in the program code within the MPLAB IDE

development environment

(#DV164005 or #DV164007,

#AC162051, ~200.00 US-$)

|

This setup programs most PIC microcontrollers (PIC12xxx,

PIC16xxx, PIC17xxx, PIC18xxx), and allows firmware updates

whenever new PIC controllers come out. I have never experienced

any issues using this commercially available programmer with the

Windows operating system (Win95, Win98, WinXP). You just have to

ensure that the intended RS232 port to use is in the range of

Com1 to Com4.

The latest version of the PICSTART Plus programmer allows

instant software-based firmware updates to the internal flash

controller. See microchipdirect.com for ordering details.

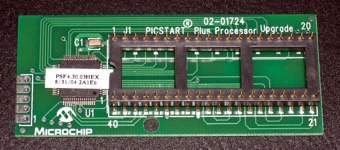

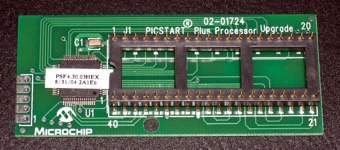

PICSTART Plus Processor Upgrade

Kit

from Microchip, includes flash-based microcontroller for

firmware upgrades

(#UK003010,

~29.00 US-$)

|

PICSTART Plus Programmer

before installing the upgrade kit, just with PIC17C44JW

and firmware v3.11

|

PICSTART Plus Programmer

after installing the PICSTART Plus Processor Upgrade

Kit

|

Years ago, I had to buy an extra PIC controller (UV-erasable

PIC17C44JW) and had to burn the corresponding firmware to it

(HEX-file supplied with MPLAB IDE). But Microchip abandoned this

re-programming procedure of the 17C44JW some times ago. Today,

the firmware upgrade of the programmer is performed directly from

MPLAB IDE, but only if you have one of the lastest flash-based

PICSTART Plus programmer, or installed the PICSTART Plus

Processor Upgrade Kit (containing a PIC18F6720) in your elderly

programmer (#UK003010, costs about 29.00 US-$, ordering information).

For ambitious starters, I recommend to order:

- In-Circuit Debugger 2 (ICD2): #DV164005 or #DV164007

(additional RS232 cable & power supply)

- 40 pin ICD header: #AC162051

- optional: Universal Programming Module for ICD2:

#AC162049

Note that with ICD2:

- the PIC16F87x can be both, in-circuit debugged and

programmed

- the PIC16F7x can only be programmed

- the PIC16F84A can only be programmed

Please see also the latest* README text files for PICSTART

Plus (17 kB) & ICD2

(32 kB)

* by 19.06.2005

|

Citing Microchip's readme.txt of PICSTART Plus

programmer:

"Program and read problem of PIC16F87X

PIC16F87X devices are shipped with low-voltage

programming enabled. PICSTART Plus programmer uses the

high-voltage programming method. Some devices do not exit

programming mode properly if low-voltage programming is

enabled, resulting in invalid read and programming

operations.

Place a 10 Kohm resistor between the RB3 pin and one

of the ground pins on the programming socket. Refer to

the device datasheet for the pinout of the specific

device."

|

First steps in PIC

programming [Toc] [Top]

As first step, read the documentation of your controller,

especially the memory and register architecture, the instruction

set (PIC Instruction Set Quick Reference) and the I/O

port section. Then try to implement a blinking LED application

using the PIC16F84 and a busy loop for waiting (you can also use

my assembler module m_wait.asm).

If your LEDs are blinking, you certainly want to connect your

controller to your PC to exchange some data. Build a RS232

hardware setup with a MAX232 level shifter and a PIC. If you use

the PIC16F84, the RS232 communication must be done by software.

You can use the 'Simple RS232 interface'. Try first to burn

the provided HEX-file onto the PIC16F84 to check for proper

hardware setup. Once everything is working well, you can get the

assembler source code and change the content according to your

needs.

Valuable Quick References

[Toc] [Top]

| MPLAB

IDE Quick Reference (DS51410B) |

Quick reference for application

development with MPLAB IDE. Summary of tools, wizards,

messages/warnings, conditional assembly, macros, samples of

absolute and relative assembler code, tips & tricks,

keyboard shortcuts.

(PDF, 188 kB) |

| MPASM/MPLINK Quick Reference (DS30400G) |

Quick reference for Microchip PIC

assembler. Summary of MPASM control directives, MPLINK

linker usage and command line options, and the individual

instruction sets of PIC10/12/16/18 devices.

(PDF, 81 kB) |

| PIC Instruction Set Quick Reference |

Quick reference of all PIC instructions,

including special instruction mnemonics. This data sheet

was extracted from document DS33014G, MPASM User's

Guide, pp. 196-209.

(PDF, 116 kB) |

Common programming questions

[Toc] [Top]

Question: What kind of instructions are BANK1 and

BNEQ?

Answer: These are my standard macro definitions

declared in the module file m_bank.asm. If

you include this module file in your main program, you can make

use of these instruction macros. For instance, the macro BANK1

performs a memory bank change to bank 1. Further, the macro BNEQ

0x23,LAB1 translates to 'branch on not equal w and 0x23'

and performs a jump to label LAB1, if the working register

w does not match the value 0x23.

Question: What kind of instructions are BNZ and SKPNZ,

since they are not listed in the Instruction Set Chapter of my

PIC controller?

Answer: These are 'Special Instruction

Mnemonics' listed in Table B.11 in the PIC

Instruction Set Quick Reference, i.e. built-in mini-macros of

the MPLAB assembler. For instance, SKPNDC translates as 'Skip

on no digit carry' and simply assembles BTFSC 3,1.

How to

assemble PIC code in MPLAB [Toc] [Top]

Only declare the main assembler file as source file in the

MPLAB project. For instance, this is the file PIC_Test.asm in the

project PIC_Test.mcp below on the picture. It will generate a

HEX-file named PIC_Test.hex when you execute 'build' or 'build

all'. Ensure that the pathes to the include files exist - or

remove the pathes and copy the include files to the directory of

the main source.

The include files must not be listed for separate compilation

under the MPLAB Project. They are just included in the main

source through include statements. During assembly time (MPASM),

these files are just inline expanded and treated as normal

assembler code. Separate compilation is neither needed nor

possible, since the code of these modules has been written for

inline compilation and (initially for simplicity) does not

contain any object or linker directives.

Of course, when project size and complexity increases, one may

consider to rewrite the code to object-based sources...

MPLAB IDE

showing the project source file (PIC_Test.asm) to be

assembled by MPASM.

|

Advanced

steps in PIC programming [Toc] [Top]

General [Toc] [Top]

Once the communication between the PIC controller and the PC

is running successfully, I suggest to implement a visual

interface on your peripheral device (the PIC controller). This

can be done easiest by using a commonly available dot matrix LCD

and one of my LCD assembler modules.

If more sophisticated I/O functionality is desired, you can

consider to attach a standard AT keyboard (ordinary PS/2 PC

keyboard) to the microcontroller. Look therefore at the AT keyboard

projects.

Paging - large code considerations

[Toc] [Top]

When your code grows, you will run into the architectural

issues of the PIC microcontroller. The PIC instruction set has

been defined - in early days - as a natural engineering trade-off

between functionality and program memory requirements. One

advantage of a larger instruction word width is the increase in

direct addressable space for immediate instructions, e.g.

'CALL Label' with Label resolved to a program

memory location by the linker/assembler. On the contrary, larger

instruction word width require more program memory, what results

in larger chip area and therefore higher manufacturing costs.

The PIC16xxx microcontroller series features immediate address

instructions (e.g. 'CALL' or 'GOTO'), which support

11 bit immediate values. Using 11 bits for immediate addressing,

we can only address 2k words in the program memory. But what if

we want to support larger memory space? One possibility to work

around this limitation is to introduce a new instruction in order

to jump between the different 2k memory blocks. That's why we

need to deal with the upper two bits ([4:3]) of the PCLATH

register. These bits cannot be altered with 'CALL' or

'GOTO' instructions, but need to be set manually before

the jump.

There is quite a good discussion and elaboration of methods to

deal with paging for the PIC16xxx microcontrollers on this site.

Using the MPLAB

IDE simulation infrastructure (MPSIM)

[Toc] [Top]

There exists a convenient built-in instruction-accurate

simulator within MPLAB IDE, called MPSIM. You can enable the

MPSIM simulator through the Debugger menu: Debugger -> Select

Tool -> MPLAB SIM.

I used it successfully for various projects, for instance

for:

- RS232 character acquisition: Using a self-created stimulus

file RS232_Stimulus_9600.sbs, it

simulates the reception of character 'u' (equal to b'01110101')

with one start bit, 8 data bits (LSB first), no parity bit, and

one stop bit.

- R/C servo signal acquisition (pulse width measurement): For

a self-made and programmable R/C servo reverse circuit using a

PIC12F615, the incoming servo signal (i.e., R/C receiver output

signal) is simulated within MPSIM using a specific stimulus

file ServoPulses_01.sbs, which performs in

total five pulses: The first two input pulses (width:

0.75 ms, 2.25 ms) are outside specifications and

check the correct error handling of the program, the next three

pulses exercise normal operating conditions (width:

0.95 ms, 2.05 ms, 1.5 ms).

Stimulus application in MPSIM simulator

Manual stimulus creation for R/C servo signal acquisition

applying a total of five pulses: 0.75 ms,

2.25 ms, 0.95 ms, 2.05 ms, 1.5 ms.

The sequence is repeated after another 9.5 ms,

restarting at 1 ms.

|

(0) SIM-N0001 Note:

Stimulus actions after 0 us

(1000) SIM-N0001 Note: Stimulus actions after

1000 us

(1750) SIM-N0001 Note: Stimulus actions after

1750 us

(5000) SIM-N0001 Note: Stimulus actions after

5000 us

(7250) SIM-N0001 Note: Stimulus actions after

7250 us

(10000) SIM-N0001 Note: Stimulus actions

after 10000 us

(10950) SIM-N0001 Note: Stimulus actions

after 10950 us

(20000) SIM-N0001 Note: Stimulus actions

after 20000 us

(22050) SIM-N0001 Note: Stimulus actions

after 22050 us

(30000) SIM-N0001 Note: Stimulus actions

after 30000 us

(31500) SIM-N0001 Note: Stimulus actions

after 31500 us

(41000) SIM-N0001 Note: Stimulus actions

after 1000 us

(41750) SIM-N0001 Note: Stimulus actions

after 1750 us

|

MPSIM simulator output

Messages of the MPSIM simulator concerning the applied

external stimuli.

|

Graphical verification of stimulus application

and output generation

The applied stimuli and generated output signals can be

graphically verified by using the built-in logic analyzer

in conjunction with MPSIM. It can be quickly ensured,

that the desired stimuli are applied at pin GP5, and the

output PWM signal is generated at pin GP2 - by

ignoring the two out-of-spec input pulses at the very

beginning.

|

MPSIM simulator settings

Check the correct project settings for simulation:

4 MHz device clock, enable 'trace all' for logic

analyzer support within simulation, adjust the trace

buffer (128 k lines).

|

Below a screenshot of a code assessment using the MPSIM

simulator, external stimuli, and the stopwatch provided by the

MPLAB IDE. It shows the the correct value of 2.05 ms for the

R/C servo signal output - after 'reversing' an acquired input

signal of 950 us. So MPSIM has been used for quick

functional verification of code having been developed from

scratch - without any real hardware involved. In fact, I didn't

have the hardware at hand during code development.

Using the Stopwatch within MPSIM for assembler

code

The stopwatch is a very convenient tool to assess the

performance of specific code sections. It can also be

used for verification of selected functionality, e.g., as

depicted, the correct R/C servo signal reversing based on

an acquired 950 us input pulse, which is finally

generating a 2050 us output pulse.

|

Using the Stopwatch within MPSIM for C

code

The stopwatch of MPLAB IDE can also be used to assess

code developed in high-level languages.

|

High-level

languages [Toc]

[Top]

C compiler [Toc] [Top]

There exist several commercial solutions to program the PIC

microcontroller in C. In the past, little of them were available

for free - but this has fortunately changed recently. Please see

the list of free C compilers below.

A very interesting C compiler comparison is provided by CCS,

Inc.

Please note, that this information is not independently verified,

but are rather volunteer contributions.

List of free C

compilers [Toc]

[Top]

This list can not be regarded as exhaustive - last update:

2010/05/11

If you know other free C compilers, you are kindly requested

to

email me. I will add it to the list below.

- A student edition of Microchip's C18 compiler for PIC18

MCUs is available for free on this site.

For 60 days, it is the full version of the PIC C18 compiler.

Afterwards, the optimizations related to procedural abstraction

and to the extended instruction set of the newer PIC18XXXX

devices will be disabled. Code compiled after the expiration

date will function but may occupy more memory space. (No

personal experience with this compiler.)

- A limited edition of HI-TECH's PIC C compiler for the

PIC10/12/16 MCU family is available for free on this site. The HI-TECH PICC-Lite compiler is free,

but with limitations in memory usage and device support, and

all optimization techniques are disabled. Due to program memory

constraints, support for printing floating-point and long data

types using printf functions is not included. (No personal

experience with this compiler.)

- A limited edition of SourceBoost's C compiler for

non-commercial use is available for free on this site. It supports 2 banks of RAM for

the PIC12/16/18 devices, and 2k words for the PIC12/16 and 4k

bytes for the PIC18 family. See also licensing and limitations. (No personal

experience with this compiler.)

- There exists an open source project called Small Device C

Compiler (SDCC). SDCC is a retargettable, optimizing ANSI -

C compiler that targets the Intel 8051, Maxim 80DS390, Zilog

Z80 and the Motorola 68HC08 based MCUs. Work is in progress on

supporting the Microchip PIC16 and PIC18 series. SDCC is Free

Open Source Software, distributed under GNU General Public

License (GPL). (No personal experience with this

compiler.)

Commercial C

compilers [Toc]

[Top]

Personally, I use the CCS C compiler for developing PIC

microcontroller code in a high-level language. I can recommend

this compiler, although I regard it as a professional tool with

respect to quality and pricing. The CCS C compiler can be ordered

with its own integrated development environment (IDE), but also

has a plugin for seamless integration into the Microchip MPLAB

IDE.

In general, it is quite useful to cross-check the assembler code

generated from C sources to get an impression what preconditions

have been assumed by certain C functions. For instance,

get_timerX() assumes a running timer and therefore generates more

code than necessary in case a timer being halted is considered.

Moreover, the granularity concerning the control of underlying

hardware blocks is usually coarse-grained. For instance, the

timer can not be halted and restarted with given C functions

(only disabled and reconfigured/enabled), instead, we need to

resort to our own specific declarations in order to gain access

to such functionality, as shown for timer 1 in the box

below.

The

CCS command-line C compiler for 14-bit opcode PIC devices,

e.g., PIC12F615, PIC12F683, PIC16F84, PIC16F877, PIC16F887, is

prepared for seamless integration into MPLAB IDE and starts at

150 US-$.

Notes on the C code below:

- By using the #BIT and #BYTE statements instead of plain

inline assembler code, I seek to properly address the bank/page

characteristics of these special function registers (SFRs) -

inherent to the PIC architecture and mandatory to be known by

any high-level language compiler - by delegating the correct

handling to the C compiler.

- Employing call by reference for function my_get_timer1()

prevents the introduction of any additional temporary variables

(scratch RAM for the call stack, would be even partly present

in conjunction with function inlining), but directly copies the

contents from TMR1L and TMR1H to the 16-bit variable

tmr_val.

#INLINE

void start_timer1() {

#BIT tmr1_en = GETENV("BIT:TMR1ON");

tmr1_en = 0x1; // enable timer 1

}

#INLINE

void stop_timer1() {

#BIT tmr1_en = GETENV("BIT:TMR1ON");

tmr1_en = 0x0; // disable timer 1

}

#INLINE

void my_get_timer1(unsigned int16 &tmr_val) { // short

variant for halted TMR1

#BYTE hi = GETENV("SFR:TMR1H");

#BYTE lo = GETENV("SFR:TMR1L");

tmr_val = make16(hi, lo);

}

|

Debugging

hints [Toc]

[Top]

General [Toc] [Top]

- Write only small pieces of new code, whenever possible

within a simplified test program.

- Most hobby-developers have no expensive in-circuit debugger

tool (real-time debugging in the target application using

specific software, with breakpoints and register watches). Use

therefore dot matrix LCD and/or RS232 interface for

debugging.

- Use encapsulated well-verified blocks, which you put

together as parameterizable building blocks in the target

application.

- For large projects, try to use object code and the linker

provided by Microchip MPASM IDE.

Compile messages &

sanity checks [Toc] [Top]

During the code development, overly generous compilation

messages are sometimes nasty and contra-productive.

Therefore, I turn off selected compilation messages during

development by using the statements below.

However, it makes sense to temporarily re-activate those

messages.

For instance, message 302 serves to check the correct bank access

scheme for selected configuration registers.

;***** COMPILATION

MESSAGES & WARNINGS *****

ERRORLEVEL -207 ; found label after column 1

ERRORLEVEL -302 ; register in operand not in bank

0 |

Recommendation: After development of the configuration

section, temporarily turn on message 302 and check all

compilation messages concerning correct bank access for

configuration registers.

Prevent page crossings of

tables [Toc]

[Top]

To prevent unintended

page crossings of tables, seek to add unique labels to the

beginning and end of each table and provide a corresponding

check, i.e., assertion. The assertion is executed during each

compilation and ensures the integrity of the table alignment.

WelcomeTable

addwf PCL,F ; add offset to table base pointer

DT "PIC 16F84 AT Keyboard Decoder connected" ;

create table

retlw CR ; carriage return

retlw LF ; line feed

WTableEND retlw LF ; line feed

IF (high (WelcomeTable) != high (WTableEND))

ERROR "Welcome table hits page boundary!"

ENDIF |

RS232 communication issues

[Toc] [Top]

In case you have built a PIC application including serial

communication (RS232), but it does not work properly, try to

debug it the following way:

1. Write a simple PIC assembler program for the PIC16F84 using

the module m_rs096.asm, for instance

based on the existing Simple RS232

Interface. Change or extend the main loop such that it keeps

transmitting a dedicated character every second, e.g. something

like:

LOOP SEND '@'

WAITX d'16',d'7' ; 1.045 s @ 4 MHz, extended with

specific prescaler

goto LOOP |

You may also use one of the communication test programs,

commtest1.asm

or commtest2.asm,

which transmit constantly status messages '@' and echo on every

received character.

2. Setup the HyperTerminal program (Win9x, WinXP) using the

standard settings as follows:

Default RS232 port settings

(9600-8-N-1)

|

Start the HyperTerminal application using the standard

settings. It should now receive a '@' every second from the PIC

microcontroller. If not, check the MAX232 and the RS232

connectors, until you receive the characters...

LCD communication issues [Toc] [Top]

Question: I can not figure out the connection between

dot matrix LCD and PIC microcontroller. Do you have a

schematic?

Answer: Basically, there is a text description in the

header section of each LCD assembler module file. But here is

also a PDF schematic to illustrate the connection between

display and controller.

Question: I have downloaded from your site the

assembler module file 'm_lcd_bf.asm' for my PIC project.

The LCD display I use is a 20x4 (CrystalFontz CFAH2004A-TMI-JP),

but it does not work. I don’t see any character and the

problem is not the contrast…

Answer: I've recently adapted some parts of the

initialization section of the LCD module files (longer wait delay

after display clear). I assume you have a newer type of display

controller than the traditional Hitachi HD44780 (PDF data

sheet, 389 kB). In case you have the LCD controller

Samsung KS0073 (PDF

data sheet, 673 kB), you have to set the constant

'LCDTYPE' to 0x1 in your main program. This adds specific

configuration commands of the new controller type, i.e. the

extended function set to set up the line count (PDF data sheet,

186 kB). You may have to adapt the line count to your

KS0073-type display in the extended function set part of

the LCD initialization section of the LCD module file (e.g.

m_lcde.asm).

If this does not help, try to use longer delays for the

initialization procedure.

Below the declarations for the module file

m_lcde.asm.First try the circuit with a 4 MHz

crystal, later on with 20 MHz. If this does not work, you

may have to adapt the initialization section to your specific

display controller (latency, commands). But first try with the

standard settings for PIC16F7x and 4 MHz:

LCDtris equ TRISD ;

LCD data on low nibble of portD

LCDport equ PORTD

#define LCD_ENtris TRISE,0x00 ; EN on portE,0

#define LCD_EN PORTE,0x00

#define LCD_RStris TRISE,0x01 ; RS on portE,1

#define LCD_RS PORTE,0x01

#define LCD_RWtris TRISE,0x02 ; RW on portE,2

#define LCD_RW PORTE,0x02

CONSTANT BASE = 0x20 ; base address of user file

registers

#include "..\m_bank.asm"

#include "..\m_wait.asm"

#include "..\m_lcde.asm" |

In case of failure, ensure that you do not use the temporary

registers at BASE+0 - BASE+3 elsewhere in your code, especially

not in your interrupt service routine (ISR)! If this setup works

perfectly, you may upgrade to the more efficient LCD modules

m_lcde_bf.asm or m_lcdexbf.asm (busy flag instead

of wait loop).

In case of errors

[Toc] [Top]

Compile errors [Toc] [Top]

If you cannot compile the projects and errors like below

appear, you did not specify the path to your include files

correctly.

Check the '#include' statements:

#include

"..\m_bank.asm"

#include "..\m_wait.asm"

#include

"..\m_rs096.asm"

|

Examples of errors generated by wrong '#include'-pathes:

Executing:

"C:\Tools\HW\Microchip\MPASM Suite\mpasmwin.exe" /q /p16F84

"LCDx_test.asm" /l"LCDx_test.lst" /e"LCDx_test.err"

Error[101] ..\..\M_LCD.ASM 113 : ERROR: (Missing include

file: m_bank.asm)

Error[101] ..\..\M_LCD.ASM 116 : ERROR: (Missing include

file: m_wait.asm)

Error[113] ..\..\M_LCD.ASM 279 : Symbol not previously

defined (LCDclk)

Error[113] ..\..\M_LCD.ASM 283 : Symbol not previously

defined (LCDclk)

Error[122] ..\..\M_LCD.ASM 290 : Illegal opcode (WAIT)

Error[122] ..\..\M_LCD.ASM 296 : Illegal opcode

(LCDWAIT)

Error[116] ..\..\M_LCD.ASM 184 : Address label duplicated

or different in second pass (BANK0)

Error[108] ..\..\M_LCD.ASM 189 : Illegal character (4)

Error[113] ..\..\M_LCD.ASM 193 : Symbol not previously

defined (LCDclk)

Error[122] ..\..\M_LCD.ASM 194 : Illegal opcode

(LCDWAIT)

Error[113] ..\..\M_LCD.ASM 200 : Symbol not previously

defined (LCDclk)

Error[122] ..\..\M_LCD.ASM 201 : Illegal opcode

(LCDWAIT)

Error[113] ..\..\M_LCD.ASM 205 : Symbol not previously

defined (LCDclk)

Error[122] ..\..\M_LCD.ASM 206 : Illegal opcode

(LCDWAIT) |

Page

crossings [Toc]

[Top]

Although most of my code is below the critical size of 2k

instruction words, page crossings may occur if you extend the

assembler source code to your needs. Please read the

recommendations about paging above.

PIC history

[Toc] [Top]

Below are some interesting text snippets found on the web

about the history of Microchip PIC controllers.

Call it RISC...

[Toc] [Top]

Citing John Bayko (Tau),

<john.bayko@sk.sympatico.ca>:

A complete version of John Bayko's interesting 'Great

Microprocessors of the Past and Present' may be retrieved at

http://jbayko.sasktelwebsite.net/cpu.html.

The roots of the PIC originated at Harvard university for a

Defense Department project, but was beaten by a simpler (and more

reliable at the time) single memory design from Princeton.

Harvard Architecture was first used in the Signetics 8x300, and

was adapted by General Instruments for use as a peripheral

interface controller (PIC) which was designed to compensate for

poor I/O in its 16 bit CP1600 CPU. The microelectronics division

was eventually spun off into Arizona Microchip Technology (around

1985), with the PIC as its main product.

The PIC has a large register set (from 25 to 192 8-bit registers,

compared to the Z-8's 144). There are up to 31 direct registers,

plus an accumulator W, though R1 to R8 also have special

functions - R2 is the PC (with implicit stack (2 to 16 level),

and R5 to R8 control I/O ports. R0 is mapped to the register R4

(FSR) points to (similar to the ISAR in the F8, it's the only way

to access R32 or above).

The PIC16x is very simple and RISC-like (but less so than the

RCA 1802 or the more recent 8-bit Atmel AVR microcontroller which

is a canonical simple load-store design - 16-bit instructions,

2-stage pipeline, thirty-two 8-bit data registers (six usable as

three 16-bit X, Y, and Z address registers), load/store

architecture (plus data/subroutine stack)). It has only 33 fixed

length 12-bit instructions, including several with a

skip-on-condition flag to skip the next instruction (for loops

and conditional branches), producing tight code important in

embedded applications. It's marginally pipelined (2 stages -

fetch and execute) - combined with single cycle execution (except

for branches - 2 cycles), performance is very good for its

processor catagory.

The PIC17x has more addressing modes (direct, indirect, and

relative - indirect mode instructions take 2 execution cycles),

more instructions (58 16-bit), more registers (232 to 454), plus

up to 64K-word program space (2K to 8K on chip). The high end

versions also have single cycle 8-bit unsigned multiply

instructions.

The PIC16x is an interesting look at an 8 bit design made with

slightly newer design techniques than other 8 bit CPUs in this

list - around 1978 by General Instruments (the 1650, a successor

to the more general 1600). It lost out to more popular CPUs and

was later sold to Microchip Technology, which still sells it for

small embedded applications. An example of this microprocessor is

a small PC board called the BASIC Stamp, consisting of 2 ICs - an

18-pin PIC16C56 CPU (with a BASIC interpreter in 512 word ROM

(yes, 512)) and 8-pin 256 byte serial EEPROM (also made by

Microchip) on an I/O port where user programs (about 80 tokenized

lines of BASIC) are stored.

Scientific curiosity [Toc] [Top]

Citing Len Umina <umina@kirk.mchip.com> from http://www.brouhaha.com/~eric/pic/faq.txt:

Actually, the PIC architecture was first integrated by

Signetics for a company in San Jose (Scientific Memory Systems as

I recall) using Bipolar technology and dubbed the 8X300. Prior to

that, the architecture had been a scientific curiosity since its

invention by Harvard University in a Defense Department funded

competition that pitted Princeton against Harvard.

Princeton won the competition because the mean time between

failure (MTBF) of the simpler single memory architecture was much

better, albeit slower, than the Harvard submission. With the

development of the transistor and IC's, the Harvard Architecture

is finally coming into its own.

Microchip has made a number of enhancements to the original

architecture, and updated the functional blocks of the original

design with modern advancements that are in concert with existing

architectural processes and enabled by the low cost of

semiconductors.

From I/O

handling to RISC controller [Toc] [Top]

Citing Alex R. Baker <alex@microchp.demon.co.uk> from

http://www.brouhaha.com/~eric/pic/faq.txt:

Back in 1965, General Instruments (GI) formed a

Microelectronics Division, and indeed used this division to

generate some of the earliest viable EPROM and EEPROM memory

architectures. As you may be aware, the GI Microelectronics

Division were also responsible for a wide variety of digital and

analog functions, in the AY3-xxxx and AY5-xxxx families.

GI also generated a 16 bit microprocessor, called the CP1600,

in the early 70s. This was a reasonable microprocessor, but not

particularly good at handling I/Os. For some very specific

applications where good I/O handling was needed, GI designed a

Peripheral Interface Controller (or PIC for short), in around

1975. It was designed to be very fast, since it was I/O handling

for a 16 bit machine, but didn't need a huge amount of

functionality, so its microcoded instruction set was small.

Hopefully, you can see what's coming....yes, the architecture

designed in '75 is substantially the PIC16C5x architecture today.

Granted, the1975 version was manufactured in NMOS, and was only

available in masked ROM versions, but still a good little uC. The

market, however, didn't particularly think so, and the PIC

remained designed in at a handful of large customers only.

During the early 80s, GI took a long hard look at their

business, and restructured, leaving them to concentrate on their

core activities, which is essentially power semiconductors.

Indeed they are still doing this very successfully now. GI

Microelectronics Division became GI Microelectronics Inc. (a

wholly owned subsidiary), which in 85% was finally sold to

venture capital investors, including the fab in Chandler,

Arizona. The venture capital people took a long hard look at the

products in the business, and got rid of most of it - all the

AY3- and AY5- parts and a whole bunch of other stuff, leaving the

core business of the PIC and the serial and parallel EEPROMs. A

decision was taken to restart the new company, named Arizona

Microchip Technology, with embedded control as its differentiator

from the rest of the pack.

As part of this strategy, the PIC165x NMOS family was

redesigned to use one of the other things that the fledgling

company was good at, i.e. EPROM - the concept of the CMOS based,

one-time-programmable (OTP) and eraseable EPROM program memory

PIC16C5x family was born.

Last updated: 2010/05/19

[Toc] [Top]